Conductive paste compound material

~Silver nanoparticles MDot®~

Conductive paste compound material

Conductive paste compound material

Silver nanoparticles MDot®

Mitsuboshi Belting's silver nanoparticle MDot® is a silver nanoparticle dispersion independently developed by our company.

As a feature, it has excellent low-temperature sinterability. It functions as a sintering aid for various conductive pastes (wiring/electrode formation, die attach) that require low resistance and high thermal conductivity at low temperatures of 200°C or less. As a key material in the advanced electronics field, we contribute to further technological innovation for our customers

What is Mitsuboshi silver nanoparticles

MDot®?

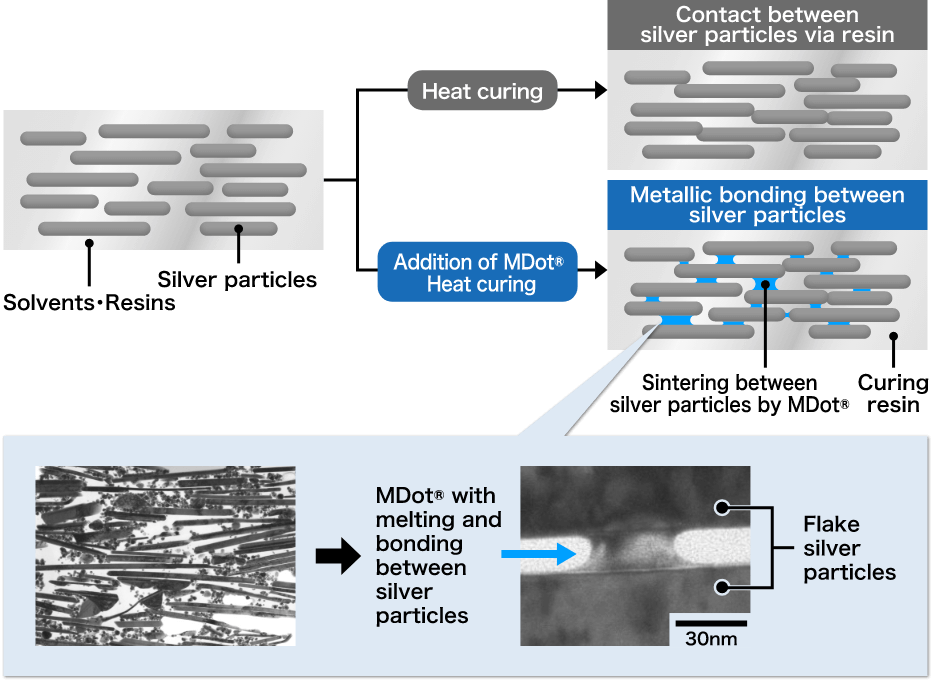

MDot® is a material that functions as an additive in conductive materials and mirror surface decoration applications.

As a conductive material, by changing part of the filler of the conductive paste to MDot® as a sintering aid, we have achieved low resistance at low temperature curing.

In addition, MDot® can be dispersed in many types of polar solvents and liquid resins. Therefore, it can be used in a wide range of applications, including conductive pastes for wiring, conductive adhesives, and conductive pastes for forming internal terminal electrodes of passive components.

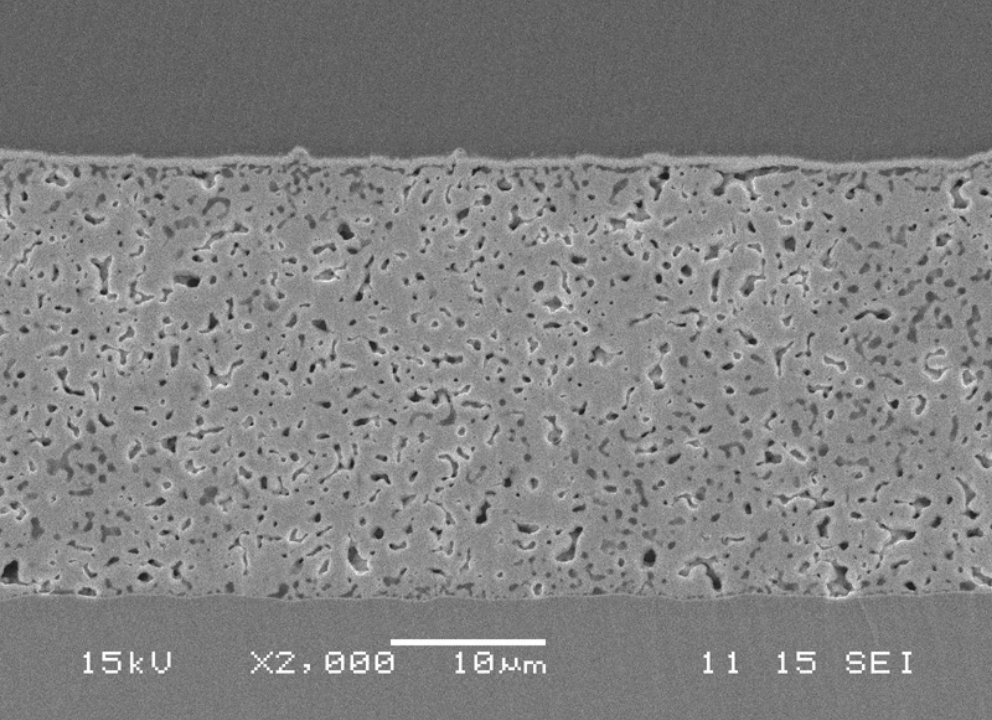

Another major feature of this product is that it provides the high reliability required for bonding materials for next-generation power semiconductor devices. It also has excellent low-temperature sinterability and can be cured at a low temperature of 200°C or less to form a dense film. By utilizing this property and using it as a filler for die attach paste, it is possible to improve the thermal conductivity and bonding strength of the bonding layer.

In addition, when used as a luster material for mirror surface decoration, a mirror-like luster can be realized by arranging silver nanoparticles with controlled particle size uniformly within the surface.

Features of Mitsuboshi Belting's silver nanoparticles

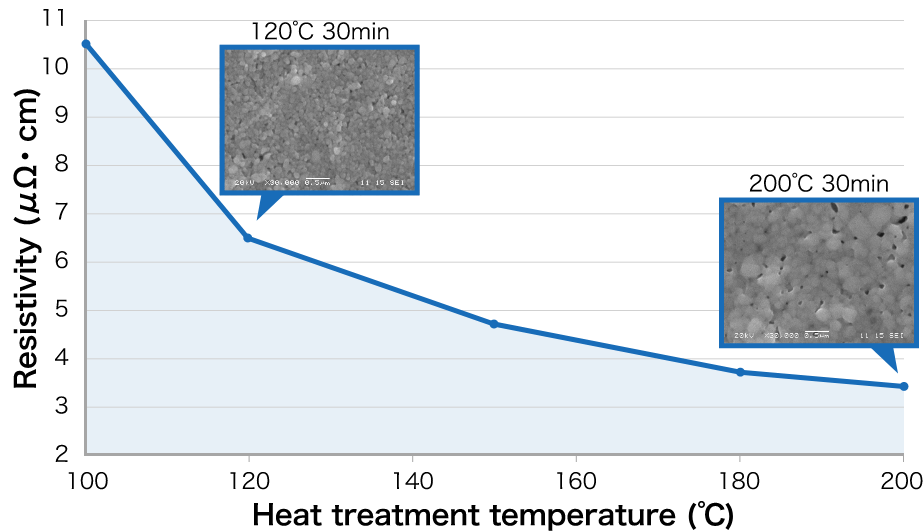

1 Contributes to promoting sintering in low-temperature processes

MDot® functions as a sintering aid for various conductive pastes (wiring/electrode formation, die attach) in the low temperature range (100-200°C) where low resistance and high thermal conductivity are required.

This material has excellent low-temperature sinterability, and exhibits electrical conductivity when the silver nanoparticles begin to fuse together at 80-100°C. Realization of this low-temperature process is expected to expand options for peripheral materials, reduce production costs, and reduce power consumption in the manufacturing process, so it will also contribute to solving social issues represented by the SDGs.

Low-temperature sinterability of MDot® alone

Functions as a sintering aid

2 Excellent dispersion stability

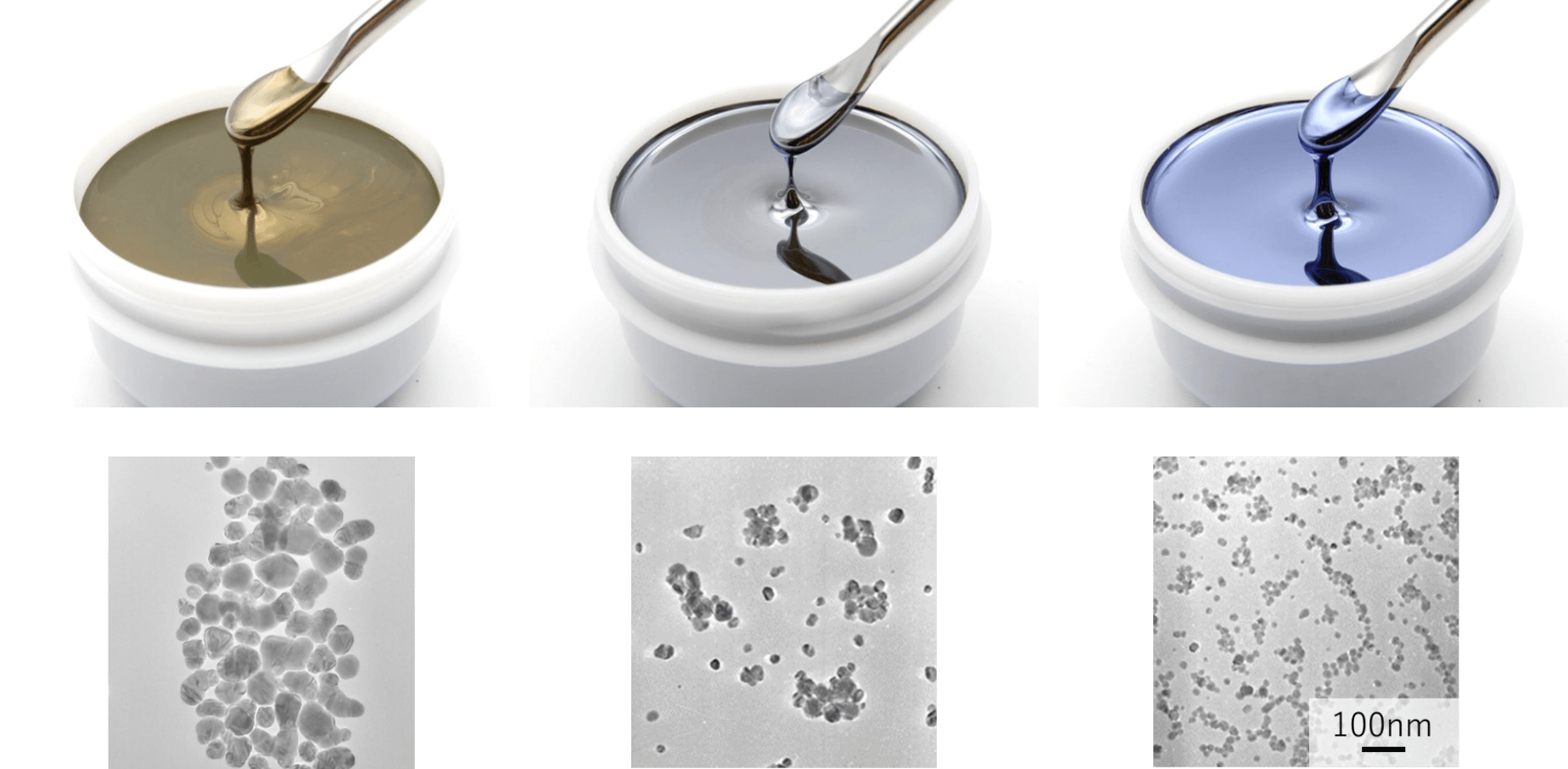

In general, reducing the particle size provides low-temperature sinterability and high thermal conductivity, but the surface of the particles is activated, resulting in lower stability.

However, MDot®, achieves long-term stability of silver nanoparticles by controlling the surface state of the nanoparticles in consideration of the balance between low-temperature sinterability and dispersion stability.

Due to this excellent dispersion stability, it is possible to provide pastes and slurries that are dispersed in various solvents and liquid resins at high concentrations (up to 90 wt%).

This product boasts an extensive supply track record as a high-quality compounding material with little variation in properties.

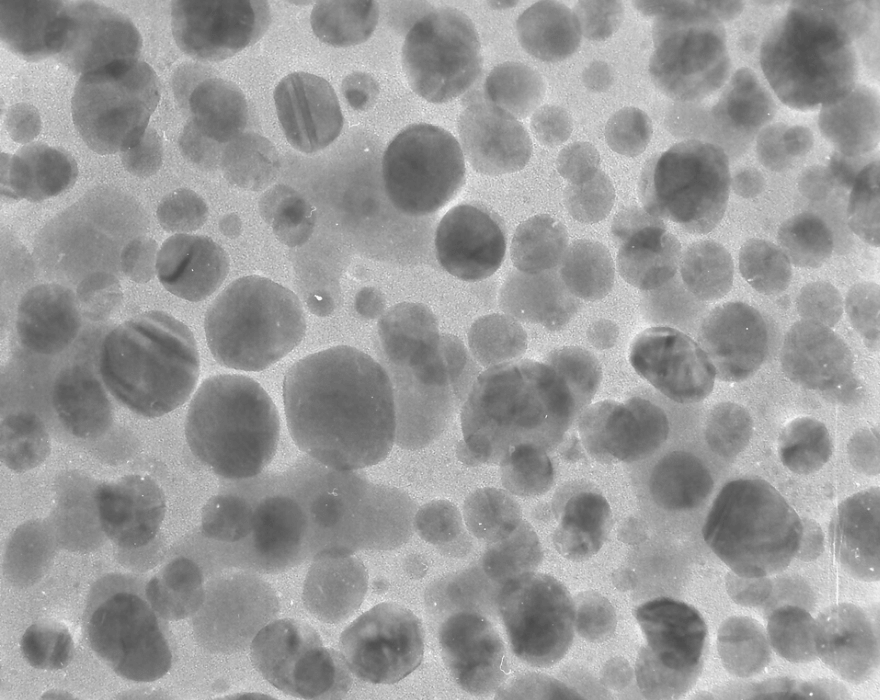

3 Particle size lineup to suit your usage

Based on the standard type (average particle size 60-100nm) that is used as a compounding material for various conductive pastes, medium particle size (30-50nm) is compatible with various conductive paste compounding materials and inkjet printing. We also offer products with a small particle size (20 nm) that are suitable for mirror surface decoration, meeting a wide range of needs.

Silver nanoparticles will be provided in a state of being dispersed in a solvent.

High concentration dispersion (~90wt%) of various polar solvents and liquid resins is possible.

| Examples of solvents with a track record of dispersion | |

|---|---|

| Diethyleneglycol monoethyl ether | carbitol acetate |

| Diethylene glycol monobutyl ether | Butyl carbitol acetate |

| Ethylene glycol | Terpineol |

| Isophorone | Dihydroterpineol |

| Liquid epoxy | Acrylate monomer |

Achievements and application examples of silver nanoparticles

Achievements and application examples of silver nanoparticles

MDot® exhibits excellent performance as a sintering aid for conductive pastes. By changing part of the conductive paste filler to MDot®, it is possible to achieve low resistance at low temperature curing. In addition, MDot® can be dispersed in many types of polar solvents and liquid resins, so it has a high degree of freedom in formulation and can be provided according to the customer’s usage.

Examples of properties as a sintering aid

When added to silver flakes

Resin content: Silver ratio 8wt%, Curing conditions: 120℃ 30min in air

When added to spherical copper powder (Silver coating 10wt%)

Resin content: Copper ratio 10wt%, Curing conditions: 190°C 30 min in air

-

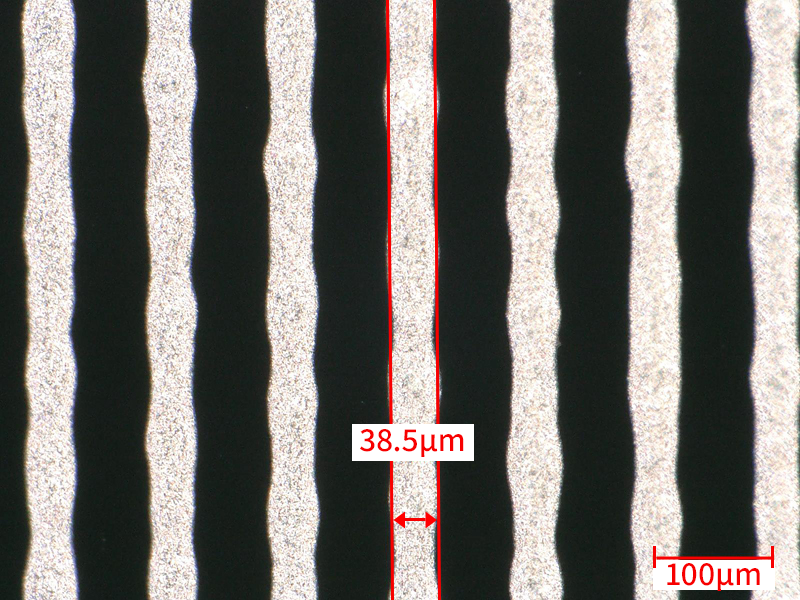

・Silver paste for wiring formation

Contributes to finer lines, and lower resistance in low-temperature, short-time firing -

-

・External electrode agent inside passive components

Contributes to low resistance and densification in low-temperature, short-time firing -

・Die attach paste, conductive adhesive

MDot® has excellent low-temperature sinterability and can form a dense film by low-temperature curing below 200℃. By using it as a filler for die attach paste, it improves the thermal conductivity and bonding strength of the bonding layer. Another feature unique to silver nanoparticles is that they provide the high reliability required for bonding materials in next-generation power semiconductor devices.